Much before KRS dam was constructed, the erstwhile Mysore state had built a huge dam in another part of the state. The reservoir created by the dam is picturesque and could potentially be a wonderful tourist spot.

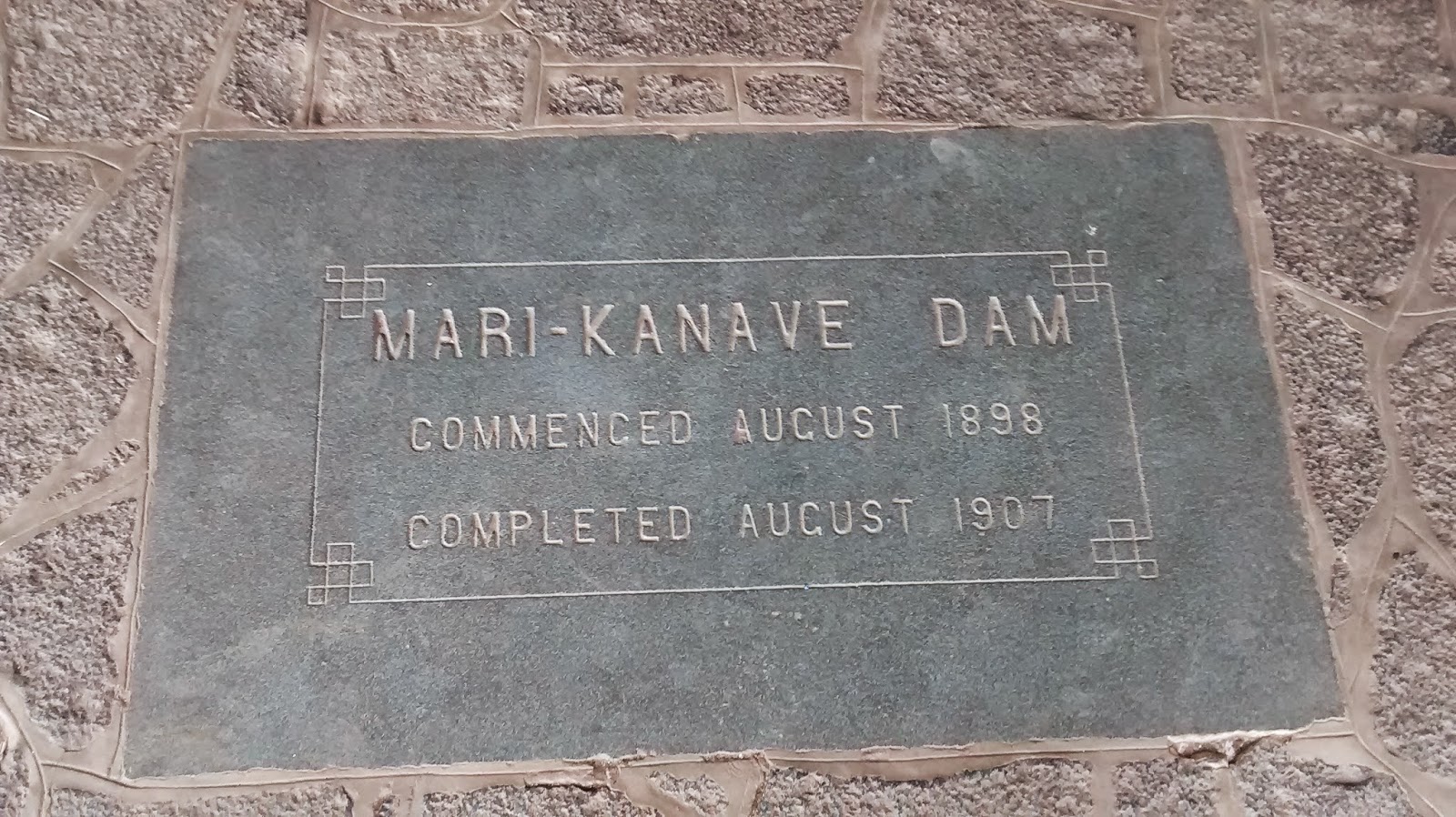

Vani Vilasa Sagar is a reservior created by the dam of the same name in Hiriyur Taluk of Chitradurga district in Karnataka. The dam is also known as Mari Kanive and is built across River Vedavati. It was built by the erstwhile rulers of Mysore state, the Wodeyars. Initiated by Dewan Seshadri Iyer, the construction of dam was started in August 1898 and it took 9 years to complete it in August 1907. The dam is named after the Queen Regent of that time Sri Vani Vilasa Sannidhana(mother of Nalvadi Krishnaraja Wodeyar after whom KRS is named). The dam is a major water source for Chitradurga town and irrigates the Hiriyur and Challakere taluks.

|

| The river downstream from the dam |

|

| Windmills on the hills adjacent to the reservoir. |

|

| Stairs for viewpoint |

Location : 13.887311, 76.489596

Getting there : From Bangalore, take NH4 upto Hiriyur. Take the Hosadurga road from Hiriyur town. Vani vilasa sagara is around 20kms from Hiriyur.

.jpg)

.jpg)

.jpg)